Homing of the Joints¶

What is Homing and why is it needed?¶

The BLMC robots, like many other robots, are using relative motor encoders. This means we don’t get the absolute position at any time but only relative position changes (e.g. “motor moved by 13 degrees”). By accumulating these changes over time, we can get the current position relative to the start position.

However, this start position can be different every time the robot is turned on. Since the absolute position is unknown, the motor controller simply defines the current position to be zero when turned on. This means the zero position as seen by the software can be at different physical positions between different runs.

To solve this problem, homing is performed in the beginning when initialising the robot. The idea is to search for a fixed physical position that can always be found, even when starting from an unknown initial position. A simple example is to move the joint in one direction until it hits the end stop (assuming it has one). As the end stop is always at the same physical position, the absolute position of the joint is now known and the zero position can be set accordingly.

Now, the position reported by the joints will always be relative to the physical zero position and are thus comparable between different runs of the robot.

Zero Position, Home Position and Home Offset¶

For better understanding in the following, a few terms have to be defined:

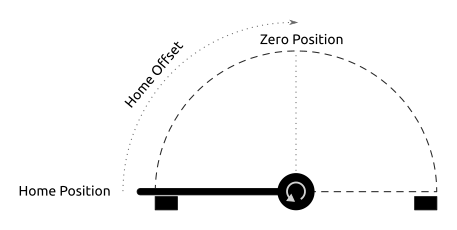

- Zero Position

The physical position at which the joint reports a position of zero (e.g. zero degrees for revolute joints). The zero position is defined by the user.

- Home Position

The home position is the joint position that is searched for during the homing. It is implicitly defined by the kinematics of the robot and the homing method that is used. For example, when using the “endstop” homing method (see below), the home position is at the end stop.

- Home Offset

Configuration parameter to specify the offset between the home position and the desired zero position.

Once the home position is found, the zero position is computed using

zero_position = home_position + home_offset

Example

Assume Alice has a revolute joint with a range of 180° that is limited by end stops on both sides. For a given application she wants the zero position to be in the middle between the end stops, such that the joint position ranges from -90° to 90°.

Alice chooses to use the “endstop” homing method (see below), searching in positive direction. This means that when starting the homing, the joint moves in positive direction until it hits the end stop. This is the home position.

Since the home position does not match with the desired zero position, Alice has to specify a home offset. As the desired position is in the middle of the 180°-range, she has to set the home offset to -90°.

The resuling configuration:

homing_method: endstop

calibration:

endstop_search_torques_Nm: [+0.2]

home_offset_rad: [-1.57]

Supported Homing Methods¶

We support a number of different homing methods. Which one is best depends on the robot and the application.

None¶

The most easy one: Do not perform any homing procedure. In this case the home position is where ever the sensors report zero (typically the position of the joint when the board was powered one).

Use this if your application does not depend on a global position (e.g. if the joint is anyway only moved relative to its current position) or if homing is already done on the motor board level.

Configuration:

homing_method: none

Home at Current Position (“current_position”)¶

Use the current joint position (at the moment when the homing is run) as home position.

Can, for example, be used in applications where the exact position is not so important and the joints are manually moved to the desired home position before running the software.

With this method, the motors do not move during homing.

Configuration:

homing_method: current_position

Home at Next Encoder Index (“next_index”)¶

The motor moves slowly until the next encoder index tick is detected. The position of the index tick is used as home position.

Keep in mind that due to gear ration between motor and joint, the motor does several revolutions for one joint revolution and thus the encoder index appears multiple times at different joint positions. Therefore the initial position from where the index search is started does matter!

This is similar to the “current position” method but here the joints only need to be moved roughly to the desired position from which it starts the index search and thus uses the exact same home position every time.

The signs of the endstop_search_torques_Nm configuration value is used to

determine the search direction for each joint (even though the actual value is

not used).

Configuration example:

homing_method: next_index

calibration:

endstop_search_torques_Nm: # only signs are relevant

- +0.1

- +0.1

- -0.1

Home at End Stop (“endstop”)¶

The motors move until they hit an obstacle (the end stop). The position of the obstacle (while still pushing) is used as home position.

Can be used in applications where all joints have an end stop that can safely be hit. Note that the exact home position can vary a bit between runs depending on the softness of the system (a joint may in some runs push a bit harder into the end stop than in others).

For this to work reliably, it is important that there are no other obstacles that might accidentally be hit by the joints instead of the end stop!

Does not depend on a specific start position.

Does not depend on the encoder index.

The torque with which each joint moves during the end stop search is configured

via endstop_search_torques_Nm.

Configuration example:

homing_method: endstop

calibration:

endstop_search_torques_Nm:

- +0.3

- +0.3

- -0.2

Home at End Stop After Release (“endstop_release”)¶

Like above but release the torque from the joints and wait a moment, so that the joints are not actively pushing against the end stops anymore before homing.

Can be useful if the joints have soft end stops (so the position may vary while the joints are actively pushing) that push the joints back. Note, however, that this requires “stable” end stops, i.e. if a joint is at the end stop and the torque is set to zero, it should not move away on its own.

Configuration example:

homing_method: endstop_release

calibration:

endstop_search_torques_Nm:

- +0.3

- +0.3

- -0.2

First Hit End Stop, Then Search Encoder Index (“endstop_index”)¶

First move to the end stops (see above), from there search for next encoder index in opposite direction.

You may use this method if only using the end stop is not accurate enough (e.g. because the end stops are soft and the “endstop_release” method is not possible in your case).

Does not depend on a specific start position.

Configuration example:

homing_method: endstop_index

calibration:

endstop_search_torques_Nm:

- +0.3

- +0.3

- -0.2

Which Method is Best for Me?¶

There is no general answer which method is the best, as it always depends on the application and the physical properties of the robot. To give some guide:

Only use methods that depend on the encoder index (next_index and endstop_index) if you don’t get accurate enough results otherwise. Using the index provides best repeatability but the home offset depends on the index position, so it needs to be calibrated individually for each robot and needs to be recalibrated each time the joint was disassembled for maintenance.

Use the end stop if possible. It has the great advantage that you can simply start the homing at any time without having to manually align the joints first. Of course, this only works, if the geometry of your robot allows all joints to reliably reach the end stop by simply moving towards it (i.e. they cannot get blocked somewhere else).

How to Determine the Home Offset?¶

Often the home position (that is implicitly defined by the robot kinematics and

the chosen homing method) does not match with the desired zero position. For

example when homing at an end stop, the home position is always at one of the

end stops but the desired zero position might be in the middle of the joint

range.

Therefore the offset between the home position and the desired zero position

(called home_offset in the configuration) needs to be determined and written

to the configuration file.

A relative easy method to find the correct offset is as follows:

First set the home offset to zero (i.e. zero position = home position).

Start the robot and perform the homing.

Manually move the robot to the desired zero position and print the position of the joints (after homing these positions are now relative to the home position).

Set the joint positions of the desired zero position as home offset.

When restarting now, the actual zero position after homing should be the desired one.

Note

When using one of the homing methods that rely on the encoder index, the home offset does not only depend on the geometry of the robot but also on the position of the index tick on the encoder disc. This means that when exchanging the encoder disc, the offset likely needs to be recalibrated. Likewise otherwise identical robots may need different offsets if the encoder discs are aligned differently in the different robots.